In modern refrigeration systems, condensers play a vital role. Its main function is to discharge the heat carried by the high-temperature gaseous refrigerant discharged by the compressor, condense it into liquid, and then complete a key step in the refrigeration cycle. The copper tube aluminum fin condenser stands out among many types of condensers with its efficient heat exchange performance and relatively light characteristics and is widely used in air conditioning, refrigeration, and heat pump systems.

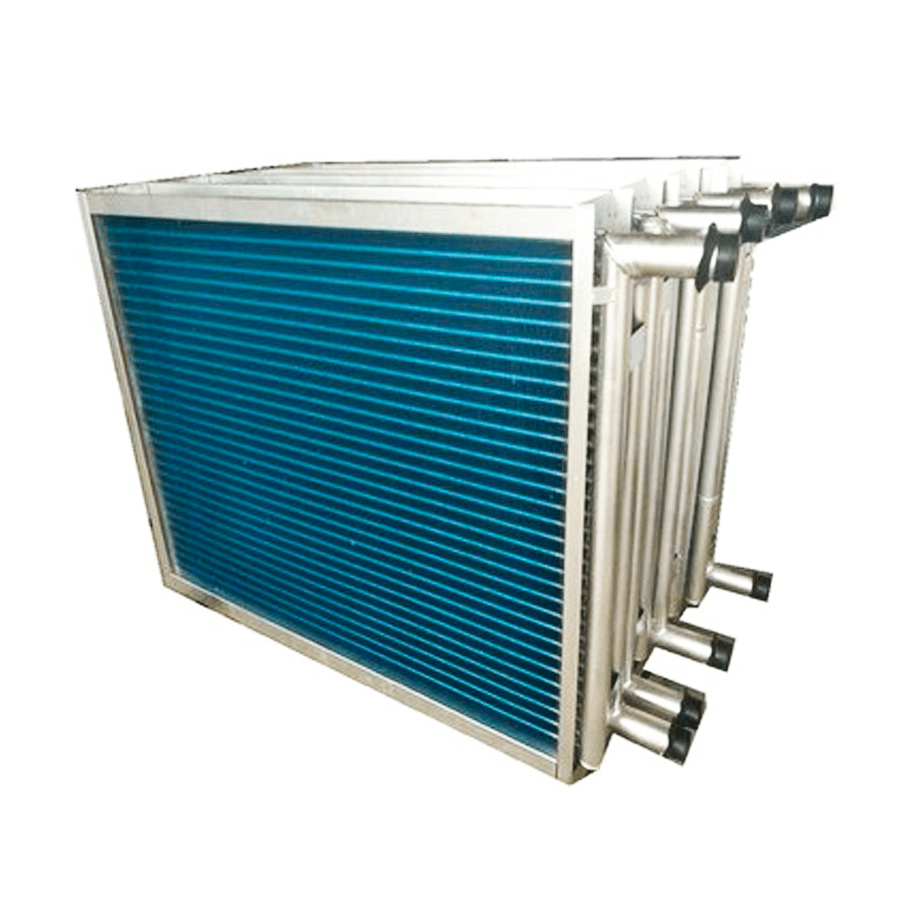

The core components of the copper tube aluminum fin condenser include two basic elements: copper tube and aluminum fin. The copper tube has excellent thermal conductivity, which enables the refrigerant to quickly transfer heat to the tube wall when it flows inside the copper tube; while the aluminum fin has a light weight and good heat dissipation ability, which greatly increases the heat dissipation area of the condenser and improves the heat exchange efficiency.

The working principle of this type of condenser is based on two heat transfer mechanisms: convection heat transfer and heat conduction. When the high-temperature gaseous refrigerant flows into the copper tube, the heat exchange effect inside the copper tube causes the refrigerant to gradually cool down and begin to condense. At this time, the close combination between the copper tube and the aluminum fin effectively transfers heat from the surface of the copper tube to the aluminum fin through heat conduction. Subsequently, the aluminum fins contact the surrounding air through the increased surface area and use convection to dissipate heat into the environment, thereby accelerating the condensation process of the refrigerant.

In the design of copper tube aluminum fin condensers, the copper tube is usually arranged as multiple parallel pipes. This configuration not only enhances the stability of the structure but also optimizes the flow and heat exchange efficiency of the refrigerant. The aluminum fins are evenly installed on the outside of the copper tube at a certain interval, forming a structure similar to “ribs”, which greatly increases the surface area of the condenser in contact with the air and promotes heat exchange.

The advantage of this structure is that it not only retains the excellent thermal conductivity of the copper material but also reduces the overall weight by adding aluminum fins, thereby improving the heat dissipation efficiency per unit volume. In addition, the diversified design of the aluminum fin surface, such as corrugation and window opening, further improves the heat exchange conditions on the air side, so that the condenser can work efficiently even in a small space or poor air circulation environment.

In actual applications, the working performance of copper tube aluminum fin condenser is affected by many factors. Ambient temperature, air flow, and the cleanliness of the condenser itself directly affect its heat exchange effect. For example, a high-temperature environment and poor airflow will reduce the condensation effect, while keeping the condenser clean can effectively improve its working efficiency.

In order to ensure the continuous and efficient operation of the copper tube aluminum fin condenser, reasonable maintenance, and care are indispensable. Regularly cleaning the dust and dirt on the aluminum fins and maintaining good airflow are important measures to improve the working efficiency of the condenser. At the same time, the refrigerant filling amount must also be strictly controlled, and excessive or insufficient refrigerant will affect the normal operation of the condenser.

As an efficient heat exchange device, the copper tube aluminum fin condenser plays an indispensable role in the refrigeration system. It cleverly combines the high thermal conductivity of copper material and the lightweight and high heat dissipation performance of aluminum material and realizes efficient heat transfer through a carefully designed structure. Correct use and maintenance are the key to ensuring its long-term and stable operation, which is not only related to the efficiency of the refrigeration system, but also the practical requirements of energy conservation, emission reduction and green environmental protection. In the future, with the development of materials science and refrigeration technology, the performance of copper tube aluminum fin condensers will be further optimized, and the application field will be more extensive, providing humans with a more comfortable and environmentally friendly living space.

As a copper tube aluminum fin condenser enterprise, we are committed to providing high-quality, high-efficiency condenser products and solutions. We have advanced production equipment and a technical team and can customize condensers of various specifications and models according to customer needs.

Leave a comment