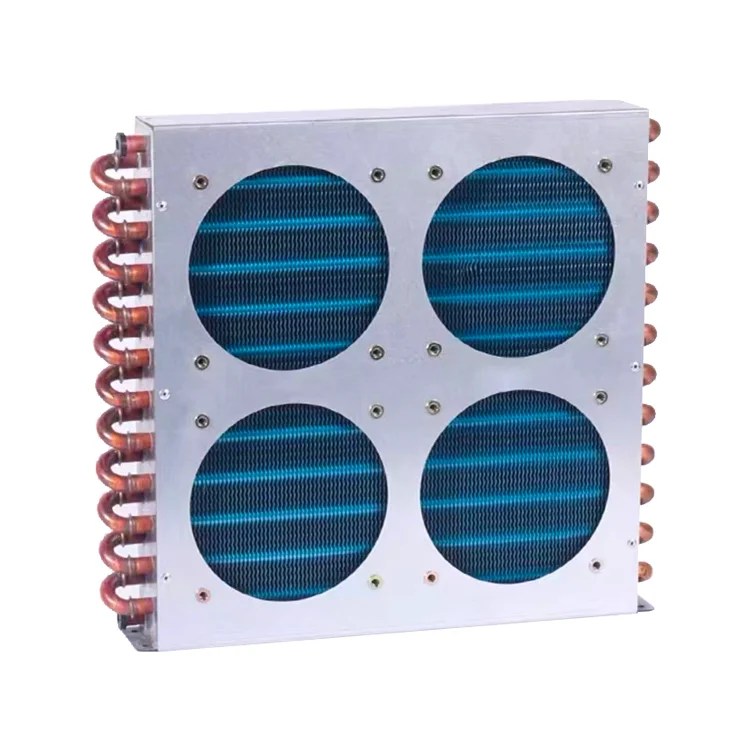

Four tuyere air cooled condenser radiator

Item code:SJ021

Product name:Condenser

Materials:Copper tube aluminum fin, galvanized plate

Tube O.D.:7mm. 7.94mm, 9.52mm, 12.75mm, 15.88mm

Aluminum fin:Hydroponic fin or bare fin

Fin type:Flat fin, Window fin, louver fin, Smooth sine wave fin

Fin space:1.1–5.8mm

Pitch of holes and rows:19.05*12.7mm; 25.5*22mm; 25*21.65mm; 31.75*27.5mm; 38.1*33mm, ect.

Application refrigerant:R417A/R407C/R404A//R410A/R134A, ect.

Product details

Copper Tube aluminum fin condenser

Item code: SJ021

Product name: Condenser

Materials: Copper tube aluminum fin, galvanized plate

Tube O.D.: 7mm. 7.94mm, 9.52mm, 12.75mm, 15.88mm

Aluminum fin: Hydroponic fin or bare fin

Fin type: Flat fin, Window fin, louver fin, Smooth sine wave fin

Fin space: 1.1–5.8mm

Pitch of holes and rows: 19.05*12.7mm; 25.5*22mm; 25*21.65mm; 31.75*27.5mm; 38.1*33mm, ect.

Application refrigerant: R417A/R407C/R404A//R410A/R134A, ect.

What applications are air cooled condensers suitable for?

Air cooled condensers are commonly used in commercial and industrial refrigeration systems, such as air conditioning systems, cold storage and refrigeration equipment. They are also suitable for some applications requiring mobile or temporary refrigeration, such as campers and mobile cold storage.

What are the advantages of air cooled condensers compared to water cooling systems?

Low maintenance costs: Air cooled condensers do not require the use of equipment such as water pumps, pipes and cooling towers, so installation and maintenance costs are lower.

Greater flexibility: Since there is no need to use water or other liquids for cooling, air cooled condensers can be more flexibly installed in any location, regardless of water source.

Greater safety: Since there is no need to use water, there are no problems such as water leakage or water contamination, thus increasing safety.

More environmentally friendly: Since no water is required, air cooled condensers have a smaller impact on the environment and do not cause damage to water resources.

More durable: Since air cooled condensers do not require the use of water, problems such as corrosion and scale do not occur, extending the life of the equipment.

Do air cooled condensers require regular maintenance?

Yes, air cooled condensers require regular maintenance to ensure they operate properly. Because air cooled condensers are typically installed outdoors, they are susceptible to dust, sand, and other debris that can clog the gaps in the aluminum sheets, reducing their cooling efficiency. Therefore, it is very important to clean and maintain air cooled condensers regularly.

Regular Cleaning: Clean the air cooling condenser regularly to remove dust, sand and other debris. Can be flushed with compressed air or water.

Check the appearance of the condenser: Check the appearance of the condenser for damage or corrosion. If so, it needs to be repaired or replaced in time.

Check electrical connections: Check that electrical connections are tight and that cables are not frayed or damaged.

Check the condenser fan: Check whether the condenser fan is running normally and whether the fan blades are clean.

Check the refrigerant of the condenser: Check whether the refrigerant of the condenser is within the normal range. If it is not within the range, it needs to be repaired or replaced.

Regular inspections: Regularly check the performance of the condenser to ensure that it is working properly and to detect problems in time.

Keep the surrounding environment clean: Keep the surrounding environment clean to prevent debris and dust from entering the condenser.